RIFA TEXTILE MACHINERY CO.,LTD

Open End Rotor Spinning,Spinning Machine for Cotton,Spinning Machine for PV

RIFA TEXTILE MACHINERY CO.,LTD

Open End Rotor Spinning,Spinning Machine for Cotton,Spinning Machine for PV

Model No.: RS30C

Brand: RIFA

Type: Spinning Production Line

Automation: Automation

Spinning Method: Rotor Spinning

Processing Material: Cotton

Producing Process: Spinning Equipment

Certification: ISO9001: 2000

Warranty: 12 Months

Customized: Customized

Condition: New

Packaging: wooden case

Productivity: 10000sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: FULL

Certificate: ISQ9000 CE

HS Code: 8445203101

Port: Ningbo,Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

RS30C Open End Machine

RS30C is the third general rotor spining, first is RS30A, then RS30B, RS30C is our newest general rotor spining machine. RS30C-A new benchmarking in rotor spinning industry

RS30C is suitable for natural and manmade fibers and their blends. There are under exhauster and upper exhauster can be chosen according to the condition of workshop.

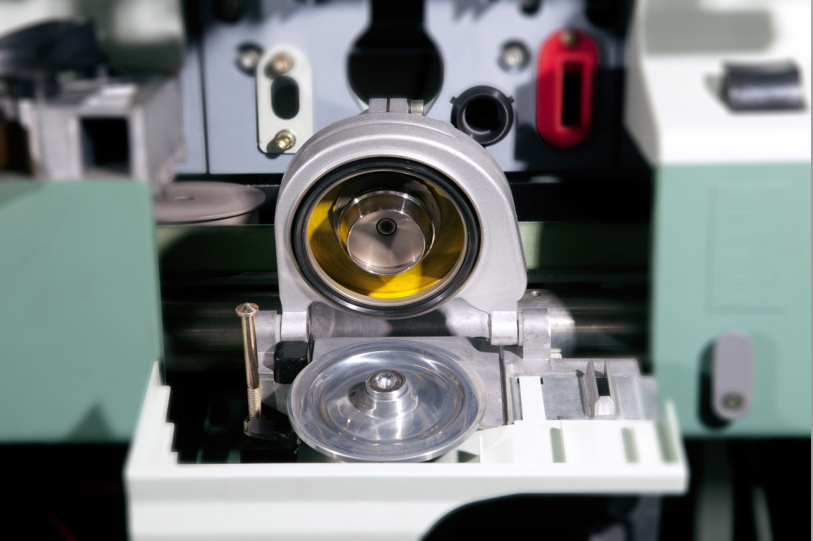

According to transfer channel and trash system with spinning experiment optimization, self-sucking spin box can produce a wider range of raw material under the high quality of finished yarn.

Individually drive sliver intake by feeding roller motor, system accurately controls piecing process to realize the high quality and consistence of piecing yarn.

Automatic lifting system can realize the creel lifts automatically after yarn breaks in order to avoid yarn wear, which also imporove piecing precision.

Traverse guiding yarn with servo system make machine with smaller vibration, lower noise and higher take-up speed.

Independent transmission on the two sides of machine, it could produce two kinds of products in the same time to meet customer' needs of multi-varieties, small batch production.

Control system is with inverter and closed-cycle control technology, which can realize spinning processing parameter in centralized setting and real-time display. Networking multi-machine to realize centralized management.

Parameter:

Dropping trash type: Trash suction

exhauster way: Under exhauster or upper exhauster

Spindles no.: Max is 520 spindles, 20 spindles per section

spindle gauge: 230mm

range of fiber length: less than 60mm

yarn counts range:Ne7--Ne36

yarn twist range: 200--2250TPM

Sliver feed: 3 Ktex--7 Ktex

Cam diameter: 500mm(max diameter)*1200mm(Max heigh)

rotor diameter: 36, 40, 46. 54mm

range of rotor speed: 40000--105000rpm

yarn guid speed: Max 200 meters per minute

draft range:20--280

take-up tension:0.95-1.06(stepless adjustment)

Loading power: 169KW(480 Spindles)

Product Categories : Rotor Spinning Machine > Semi-automatic Rotor Spinning Machine