RIFA TEXTILE MACHINERY CO.,LTD

Direct Twister Cord Thread,Direct Twister,Thread Twister,Handy Thread Twister

RIFA TEXTILE MACHINERY CO.,LTD

Direct Twister Cord Thread,Direct Twister,Thread Twister,Handy Thread Twister

1. Direct Twister Cord Thread main Functions and Usages

The TC21 series cord straight Twisting Machine is a one step twisting equipment that directly combines and twisters 2 untwisted silk yarns by means of the rope splicing twisting and is applicative for the twisting of polyester, nylon, aramid fiber, polypropylene, rayon and other industrial yarns. The machine is featured with big package, low power consumption, less labor, short process, and high quality of obtained cord thread. It is also a high efficient and energy saving industrial yarn twisting equipment and its single spindle can save up to 40% of power consumption compared with traditional twisting machine.

2. Direct Twister cord thread main Features:

2.1. Adopt the patent energy saving technology of [controlling balloon" and can reduce up to 40% of the power consumption and reduce 30% of the balloon noise at the most.

2.2 Use high efficiency and energy saving motor, each single motor drives independently and the highest spindle speed can reach 11000rpm.

2.3 Use the advanced twisting technology to reduce the length difference of the each yarn to the minimum.

2.4 The spindle motor, the overfeed roller and the winding roller can stop the spindle independently, making the operation of twisting position simple and safe.

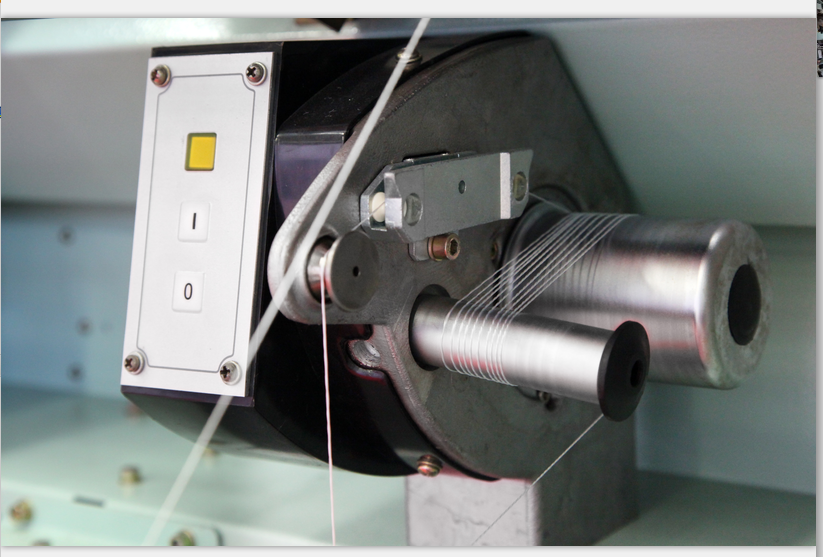

2.5 Fast and flexible pneumatic yarn threading device.

2.6 Each twisting position is equipped with yarn guiding compensation and monitoring devices to ensure excellent product quality.

2.7 The centralized adjustable constant winding tension ensures excellent bobbin forming, fine winding performance and reduces the winding difference.

2.8 The stable and recoilless hinge creel rocker arm makes the operation of the twisting positions convenient and efficient.

2.9 Equipped with doffing delivery device.

2.10 The process is convenient to adjust and the transmission system can achieve step-less speed regulation.

2.11 Better silk rolling unit to reduce breakage and increase the full bobbin rate.

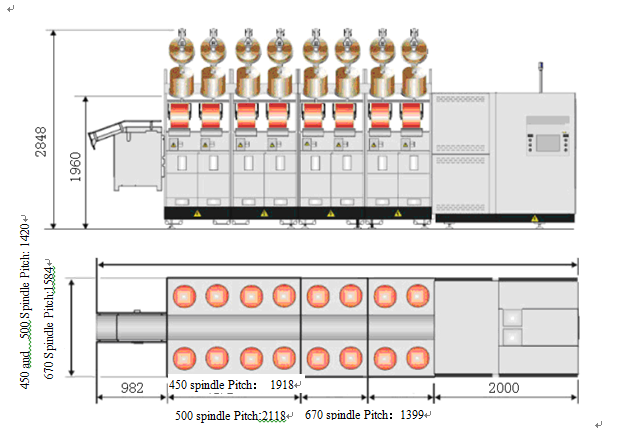

3. Technical Parameters:

a, Control system: PLC control

b, Applicative fineness: 940---2520Dtex

c, Number of spindle: 8 spindles per section, standard is 168 spindles

d, spindles: Specification: Ф205/Ф230/Ф250/Ф290/Ф300/Ф330, single motor independent drive, standard specification: Ф230mm

e, spindle speed range: 4000-11000r/mim

f, Twister range: 61-1375TPM

g, Twisting direction: S or Z twisting

h, Yarn Tension Device: Hysteresis Tension Device

i, Size of Reversing Bobbin (Diameter×Length):(Ф54~Ф110)×(200~300)

J, size of winding bobbin: (Ф70~Ф90)×290±5

k, Winding Stroke: 254mm

l, Winding Diameter: Maximum ø350mm

m, Yarn Reversing Diameter: Maximum ø230mm

n, Machine Installation Power: Maximum: 179.12kw

o, Starting Mode: soft start

p, winding angle: 15°~25directly set (step-less adjustable)

q, Yarn lending speed: 8--60m/min

r, Yarn threading air pressure: 40±0.5bar

Except twister machines, we also have all kinds winding machine, rotor spinning, OE machine, knitting machines, compact conversion, and all kinds looms